Progressing towards sustainability with energy data management

Highlighting the example of the Celarevo brewery in Serbia, owned by the Carlsberg Group, Christoph Dorigatti, Vice President of global business development at COPA-DATA looks at how companies can progress toward sustainability with an automated energy data management system (EDMS).

5th June 2024

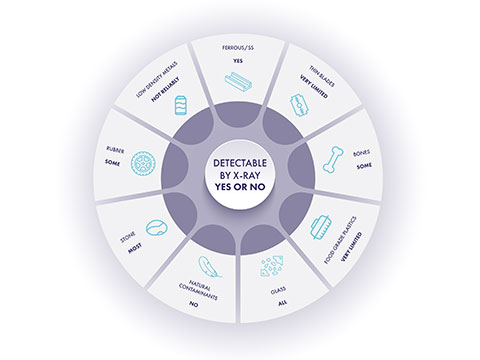

Tips On Choosing Complementary Food Inspection Technologies

Creating a 'best-in-class' contaminant detection strategy requires understanding the respective strengths and limitations of food inspection technologies. X-ray and metal detection both have the same quality control goal - detecting contaminants. Both have a place on food production lines, and when used together, both can strengthen food safety, as Phil Brown, European Sales Director at Fortress Technology, explains.

30th May 2024

Corrugated tubes improve heat exchanger performance

Over the last forty-plus years, HRS Heat Exchangers has gained a reputation for producing highly efficient tubular heat exchangers which provide unrivalled heat exchange capacity combined with consistent performance with a relatively small operational footprint. The key to this is its use of corrugated tube technology. Global key account director Matt Hale looks at the numerous benefits corrugated tubes provide over the use of smooth tubes in tubular heat exchangers.

21st May 2024

Shaping the future of food manufacturing

Paul Carter, Sales Manager at FANUC UK, looks are how robots are set to shape the future of food manufacturing.

21st May 2024

Dairy inspection sensitivity gets smarter

Food safety specialist Fortress Technology addresses the main metal detection challenges that arise when inspecting dairy applications for contaminants, reviewing how the latest technology is smarter and overcomes a number of sensitivity challenges.

14th May 2024

Upgrade weighing systems for more efficient and error free production

By implementing smart and adaptable weighing technology in plant machines and equipment, Stephen Hayes, managing director of Beckhoff UK, explains why food manufacturers require control automation to increase efficiency and prevent avoidable costs.

13th May 2024

Tips on choosing complementary food inspection technologies

Creating a 'best-in-class' contaminant detection strategy requires understanding the respective strengths and limitations of food inspection technologies, as Fortress Technology European sales director Phil Brown explains.

10th May 2024

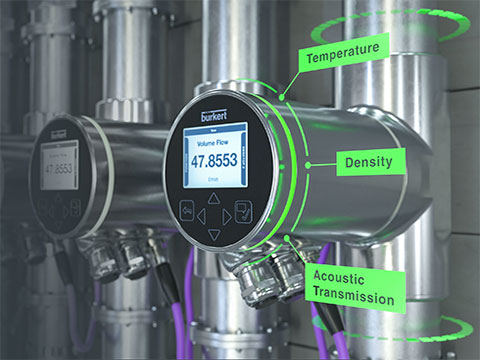

Perfecting the control of hygienic batch sizing

Kieran Bennett, industry manager for food, beverage, chemical and petrochemical at Burkert looks at the importance of process accuracy and how it can be achieved with innovative flowmeter technology.

29th April 2024

Fortress Technology makes digital data work smarter

With production data driving the digital era, food safety specialist Fortress Technology reviews how, at the push of a button, automated data collection and record keeping provides valuable insight that powers decision-making and operational effectiveness on food processing lines.

23rd April 2024

Environmentally friendly removal of phosphorous in wastewater

Many industrial manufacturing processes will result in the production of acidic waste streams. Where these undergo on site treatment, they are likely to require neutralisation before discharge, in order to comply with a discharge consent, as the experts at OMEX Environmental explain.

17th April 2024