Two approaches to using AI in control systems

In the 1971 film, Willy Wonka, an egg testing machine decides that Veruca Salt is a bad egg and sends her down the waste chute after she sings, I Want it Now. But does the egg tester use machine learning or a neural network to decide? Here, Ivalyo Ivanov, support engineer at PC-based control specialist Beckhoff UK, compares two tools in the AI toolbox.

1st July 2025

Multiple roles for heat exchangers in coconut processing

Francisco Hernandez Ortiz, global food projects director at HRS Heat Exchangers, discusses thermal processing considerations for coconut products.

30th June 2025

Helping bakery hygiene rise to the challenge

According to experts from Regal Rexnord, the best way to improve hygiene in bakeries is not just through cleaner materials or easier access, but by reducing the number of potential failure points across the system as a whole.

23rd June 2025

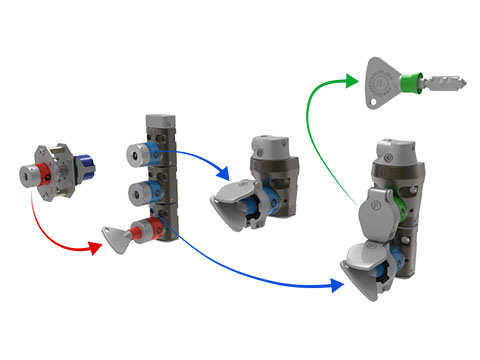

Main changes in the ISO 14119 standard for interlocking devices

The updated ISO 14119:2024 standard - covering interlocking devices associated with guards - was published just a few months ago, replacing the 2013 version. This revision is essential for machine builders, end users, and safety professionals. The experts at Fortress Safety discuss the changes.

20th June 2025

A simple guide to checkweighing in food production lines

If you think weighing is just about measuring weight, think again. Frank Borrmann, market manager for the strategic business unit checkweighing and vision, Mettler-Toledo Garvens explores the important role this technology plays in food manufacturing, helping businesses meet weighing regulations, uphold product quality and boost productivity - all while keeping production lines running smoothly.

9th June 2025

Embedding smart conveyor design in your bakery

Few things are more disruptive to a busy bakery than unplanned downtime. Whether it's a jammed conveyor, a worn-out bearing, or a belt that takes too long to clean, even small interruptions can cascade into lost batches, missed delivery windows and rising costs, as the experts at Regal Rexnord explain.

6th June 2025

How product inspection can help compliance with BRCGS global standards

In this joint Q&A, Rob Stevens, Market Manager from Mettler-Toledo Product Inspection and Merce Sanchez, Food Programme Manager, BRCGS offer insights into compliance nuances, the pivotal role of product inspection and actionable strategies to help manufacturers thrive in the face of rigorous standards.

5th June 2025

Routine testing of metal detectors is essential for food safety

Metal detection is a crucial technology for food safety, helping manufacturers maintain high quality standards while meeting regulatory and retailer requirements. However, to be truly effective, metal detectors must undergo routine testing to verify performance, confirm compliance and reduce contamination risks, says Rob Stevens, Market Manager, Mettler-Toledo Safeline Metal Detection.

4th June 2025

How to choose the right industrial bearing for your application

With so many options available, selecting the right bearing for your application can be a daunting task. Here, Chris Johnson, managing director at SMB Bearings, unravels the complexities of bearings and offers expert guidance on what to choose and when.

3rd June 2025