The new standard for flexible manufacturing with modular systems

Consumer habits are changing, and thus so are the requirements of the process manufacturing industries. Here, Bradley McEwan, business development manager at Beckhoff UK, discusses how software and modular hardware enables easy integration of technologies, like robotics and vision, that were once considered ‘standalone’.

11th April 2024

Hygienic motion solutions for food packaging machines

Maintaining hygiene is vital in food packaging machinery, and it’s important that the approach to achieve it minimises downtime to maintain productivity. Gerard Bush, engineer at motion specialist INMOCO, discusses hygienic design and servo systems for food packaging machinery.

10th April 2024

Addressing the needs and challenges faced by LabVIEW users

Beckhoff UK was a gold sponsor at LabVIEW technical event GDevCON. Here, technical support engineer Chris Knight explains the vital function that inputs and outputs (I/O) communication plays in connecting systems, exchanging data and ensuring efficient automation.

9th April 2024

Can generative AI mitigate food industry labour shortages?

With an aging workforce and a lack of younger people entering the industry, it’s clear that the UK’s manufacturing sector will face an ongoing shortage of workers. Embracing technologies like generative AI could go some way in overcoming it, as Stephen Hayes, managing director of Beckhoff UK explains.

3rd April 2024

The strategic value of food safety digital maturity

As the food supply chain undergoes modernisation and calls for heightened transparency in food safety grow louder, food manufacturers find themselves facing the need to embrace digitalisation. According to Ian Scott-Mance, technology manager at Mettler-Toledo Product Inspection, rather than viewing this as a challenge, they should perceive it as a strategic opportunity to unlock significant value for their businesses.

3rd April 2024

The role of CBM in the food and beverage industry

Food processing plants typically run their equipment for 16 to 20 hours a day, yet a Forbes report claims that manufacturers face an average of 15 hours downtime per week. Tom Cash, director of Siemens parts supplier, Foxmere, explains how the role of condition-based maintenance (CBM) helps maintenance engineers recognise gross defects before catastrophe strikes.

25th March 2024

Minimising downtime to help combat manufacturing costs

For manufacturers, keeping a close eye on their Overall Equipment Effectiveness (OEE) numbers, the last thing they want is unscheduled downtime messing things up. Kati Hope, global account manager of Mettler-Toledo Product Inspection, shares information on how picking the right product inspection system can be a game-changer for keeping the production line humming and decreasing spend for food manufacturers.

25th March 2024

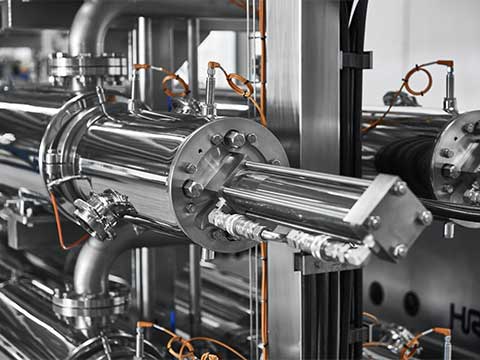

Choosing the right heat exchanger for food processing

In the simplest terms, a heat exchanger is like a radiator, designed to heat (or cool) one material from another. However, over the last 150 years or so, a wide variety of types and designs have emerged, meaning that finding the most suitable type of heat exchanger for your application is not always simple. Matt Hale, international sales and marketing director at HRS Heat Exchangers, looks at the considerations for choosing the right heat exchanger for food processing applications.

21st March 2024

Low flow liquid measurement in food industry applications

Whether syrups and flavourings for beer or soda, low flow flowmeters are required to dose these concentrated fluids at the end process, dispensing the precise amount of liquid to the correct dilution. However, the smaller the flow, the trickier it is to control and measure, and finding a suitable flow measuring technology at reasonable cost can prove challenging for both users and flow sensor manufacturers, as the experts at Titan Enterprises explain.

18th March 2024

Maxmise space, minimise waste on food production lines

Factory real estate prices are on the rise, ingredient and overhead costs are escalating, and food safety regulations are becoming stricter. Jodie Curry, commercial manager at Fortress Technology Europe, highlights the benefits of optimising food production facilities using space-saving, smaller-footprint inspection solutions.

12th March 2024