Posted to News on 30th Nov 2006, 21:00

Piezo technology to bring benefits to machine builders

Jon Severn interviews Simon Powell, chief executive of Servocell, who believes that machine builders will soon be taking advantage of piezo-based locks and interlocks.

Piezo technology is very simple in principle: apply an electric charge to a piezo crystal and it changes shape; remove the charge and the piezo crystal returns to its original shape. Making use of this technology, however, takes a little more cunning. Servocell now has a number of patents relating to piezo-based mechanisms and the company bases its current family of products on piezo-ceramic crystals bonded to metal substrates to form slender cantilevered beams (unimorphs) that bend in a similar way to bimetallic strips.

Once again, turning this into a saleable product requires ingenuity and sound design and development skills. Today Servocell is focussed on developing miniature actuators that OEM customers can build into innovative locks. In addition, because the security industry is currently benefiting from strong demand for existing products - and is therefore reluctant to devote resources to new product development - Servocell has developed its own 'ready to go' range of locks that it can sell directly and that OEMs or distributors can badge as their own.

Machine builders may have a small number of direct applications for Servocell's miniature actuators, especially the weatherproof AL2 module that is robust enough for industrial applications in temperatures ranging from -25 to +60 degrees C, but by far the most promising applications for piezo actuators are within locks and safety interlocks. Indeed, Simon Powell believes that installing piezo-based locks could cost so little that machines will be fitted with more interlocks than is currently the case, which could help to raise productivity.

Low power consumption

One of the reasons why piezo-based locks will be cheap to install is that they are very low-powered devices; power consumption is on a par with LEDs, at just a few milliwatts. What this means is that they can be battery-powered or solar powered and they can receive instructions via a radio link rather than conventional hard-wiring. Alternatively, they can receive their power and signals from a fieldbus.

Although piezo actuators are low-powered, and the movement and force applied by the unimorph are both low, this does not infer that they are only suitable for lightweight applications. Servocell has successfully used the piezo actuators within lock mechanisms that have a holding force of 4kN or more, which is easily enough for guard interlocking and similar applications. It is the knowledge of how best to apply the actuators that Servocell sees as its competitive advantage.

Aside from guard interlocking, other machinery applications for piezo-based locking mechanisms include almost anything where a conventional key-operated lock might be required, including cabinet locks and padlocks. Advantages of keyless locks include a reduced requirement for key management, increased scope for remote access control and supervision, resistance to tampering and the facility for operation via a network or wireless link.

Instead of a key, users might be issued with a code to be entered into a keypad, or a proximity card, fob or I-Button. Servocell has even contributed to the development of lock systems that utilise fingerprint recognition and vibration coding.

As an indication of the size of lock products that could be developed, Servocell has already produced a 'ready to go' cabinet lock that is about the size of a beer mat and just 12mm high. At the heart of this is the weatherproof AL2 actuator.

From waterproof to weatherproof

Servocell found that, while it was relatively straightforward to develop a waterproof actuator, making it vapour-tight was more difficult. Simon Powell explains: "Initially we thought that filling the actuator with silicone oil and sealing it with elastomeric seals would suffice. However, water vapour will always penetrate polymers, so you have to seal with metal, glass or ceramic. For sealing the moving part we therefore developed a nickel bellows - which is now manufactured in China - and the electrical feedthrough is sealed with a glass frit. The stainless steel body is fully laser welded to complete the seal, and a desiccant pill inside absorbs any residual moisture."

Throughout the AL2 project, the aim has been to develop a product capable of surviving at 55 degrees C and 85 per cent relative humidity for 2000 hours. The bellows are designed to last for 4 million cycles, and the actuator has operated for over 1 Billion cycles without failure. The complete AL2 module will be warranted for 500,000 cycles.

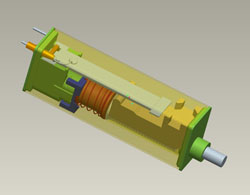

In order to maintain the same overall dimensions for the actuator (10mm wide, 14mm high and 50mm long), despite the bulky bellows, the internal latching module had to be made considerably more compact - just 12mm long. This was achieved by using a mechanism that is similar in concept to a 'pip pin' (quick-release pin), with four 2mm balls that are only permitted to move radially inwards to release the sprung latch when the unimorph is in the correct state. This is more costly to manufacture than the equivalent mechanism in the AL1 Active Latch module, but sourcing the main metal-injection-moulded (MIM) stainless steel component from India has helped to keep costs at an acceptable level.

Moisture-resistant coatings

In a separate development, Servocell is leading a research project, backed by the UK's Department of Trade and Industry, to find a coating that will make the unimorph resistant to moisture. Such a coating will eliminate the need for hermetic sealing, which will enable actuator modules to be manufactured at a much reduced cost. Meanwhile, the AL2 is a highly capable design, or the AL1 can be built into sealed assemblies - as a motorcycle manufacturer is currently doing for the ignition switch on one of its new models.

Additionally, the AL5 Active Latch module, which is expected to be in field trials by Q3 2007, will be capable of releasing while under load (the existing AL1 and AL2 Active Latch modules cannot). This new module may therefore be better suited to machinery applications, as any lock using this module will be guaranteed to open, even if, for example, mechanical damage to a guard means the lock is continuously loaded, or an operator is already trying to open a guard when the interlock is released.

Servocell is already working with Castell Safety International, which has incorporated an AL1 latch module in its Salvo drive-away prevention system that prevents the release of a lorry's air brakes until warehouse loading bay doors have been closed. Nevertheless, Servocell is seeking other manufacturers in the industrial sector that wish to develop products incorporating Active Latch modules. Following a flotation on the AIM stock market in March 2006, Servocell is in a position to offer fixed-price development projects, which means that it can effectively underwrite product developments undertaken on behalf of customers, subject to there being an acceptable business case. Six such projects are currently underway, with a good success rate reported by Simon Powell, who considers the growth in sales to be worth the investment.

Servocell is actively seeking partners in the machine building marketplace, both to help with specification and to sell the resulting products. Machine builders are welcome to contact Servocell to outline their requirements so that the company can get a clear picture of the market potential.

Servocell's website is at www.servocell.com.