Posted to News on 9th Nov 2023, 09:15

Optically clear potting compounds

Kevin Brownsill, learning and development manager at adhesives, dispensing equipment, and curing specialist Intertronics, explores the considerations when specifying an optically clear compound.

Potting and encapsulation are common methods used to protect electronic and LED assemblies from shock, vibration, and the environment. In applications where it is important to be able to see through the material, manufacturers typically specify an optically clear product. Here

Sometimes, the circuitry can’t remain hidden. The biggest application for optical potting compounds these days is when the circuitry contains LEDs for illumination, which can be in anything from traffic lights to torches.

Another reason for using an optical potting compound is when the electronics contains indicator lights or displays, and these need to be seen. Sometimes, light needs to get in, for a sensor. If these circuits require protection from the elements, then there are two main choices – seal them into an enclosure with a clear window, or pot them with a clear resin.

Environmental protection

Manufacturers may need to protect electronic assemblies from dust, debris, moisture, pressure, impact, vibration, and chemicals. The level of protection required from potting or encapsulation depends on the final environment in which the product will function.

Underwater swimming pool lights, for example, will need to be fully waterproof to IP68, as well as resistant to chlorine and other chemicals, whereas indoor lighting will require a lower level of water resistance. Potting compounds may require to be hard or scratch resistant if they might be walked on or subject to potential vandalism, for example.

As well as assessing the environment, the design engineer can consider the sector the product will be supplied into. Companies that supply into military assemblies, such as lighting for war ships, may need to consider Mil-SPEC testing of physical characteristics relating to operational durability, ruggedness, and reliability. If the optical adhesive is being designed into a medical device, the designer will need to consider meeting ISO 10993.

Specifying an optical adhesive

Once the design engineer has established the level of protection needed and what testing will be required to assess for it, they can begin to narrow down appropriate chemistries that achieve the desired hardness, clarity, resistance to yellowing, and process benefits.

There are multiple chemistries of optically clear encapsulant and potting compound available including UV acrylics, silicones, epoxies, and polyurethanes (PUs). It is important to note that there is no perfect adhesive, all materials come with advantages and disadvantages that must be weighed up.

However, polyurethanes are typically recommended as the first chemistry to test, as they are versatile, reasonably priced and have good UV resistance, ie they can be formulated to be non-yellowing and colour stable. Cured, they can be quite resilient or very hard. Intertronics’ most popular polyurethane products are the Opti-tec 4000 and 4200 range.

One drawback of PUs is that they are sensitive to moisture before cure, so must be kept dry during storage and application. Polyurethanes are hygroscopic and readily absorb moisture from the air, which reacts to form a gas. Consequently, they are packaged in airtight containers and/or with desiccants.

Taking care in handling the materials in accordance with the manufacturer’s recommendations can prevent problems later. PCB assemblies to be protected with PU compounds may need to be baked-out to ensure they are dry. Best practice would suggest cleaning of contaminants, drying, and allowing parts to acclimatise before processing, as well as ambient temperature control during processing.

Epoxies are a cost-effective option, which offer high temperature and chemical resistance and perform well in salt water or mineral/oil-based environments. However, they tend to yellow with exposure to UV/energy, and so are typically selected for applications where yellowing is not as important as other properties.

Epoxies are often used for smaller applications, as their exotherm during cure in larger volumes can lead to a loss in clarity. In one recent example, a customer was experiencing yellowing when using 2 ml of epoxy for potting during the assembly of lighting for emergency vehicles. We recommended they switch to a PU, which resolved the problem.

Silicones offer good clarity, are suitable for potting large areas, and are relatively soft when cured, which can be advantageous for products in environments that are subject to extremes of shock or temperature. They are available in gel formulations, where they retain a jelly-like consistency even post cure. They are UV resistant and tend not to discolour, while offering good temperature resistance of up to 200C.

Building a process

When specifying an optical adhesive, considering the packaging your material will be supplied in can impact your process as well as your costs. For smaller runs, cartridges or twinpack sachets are a more suitable option, whereas for high volume applications, bulk containers might be more efficient.

PU, silicone, and epoxy potting compounds are predominantly two part materials, which means you will need to ensure the materials are mixed correctly and dispensed accurately. An experienced adhesives provider can talk you through setting up a repeatable process.

Available process options range from manually mixing and dispensing from a twinpack, dispensing from a cartridge through a static mixing nozzle, right through to metering, mixing and dispensing equipment, fed from bulk containers. For applications where the highest accuracy is required, a preeflow eco-DUO precision metering, mixing and dispensing system offers accuracy of ±1%, >99% of the time.

For small area and shallow encapsulation, UV cured acrylics may be a good candidate to trial. They are single part, easy to handle, fast curing, and, compared with room temperature alternatives, reduce work in progress (WIP). One option is Dymax 9000 Series Encapsulants, which have high ionic purity, excellent adhesion, and resistance to humidity and thermal shock to effectively protect components. For applications where shadow areas are a concern, the Dymax 9100 Series offers a secondary moisture cure.

A deep sea fishing application

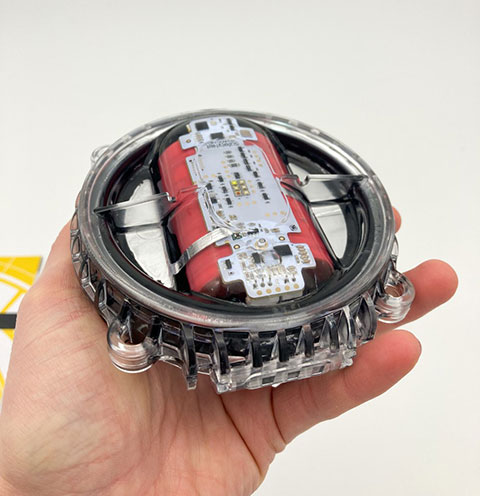

Intertronics recently assisted a sustainable fishing start up, SNTech, with the development of Pisces, a sophisticated kit of ten LED lights that fits onto fishing gear to enable more precise fishing. Pisces was rated to 20 to 30 bar pressure (around 250 metres), and SNTech’s team was developing a new model for use at 1,000 metres.

The device works by exploiting a natural behavioural response of fish – different colours of light will attract some species of fish, while scaring others away. The correct wavelength of light is essential to how the product functions, making optical clarity important for material selection. Because the potted resin would form part of the outer surface of the device, the material needed to be scratch resistant, UV resistant, capable of withstanding thermal shock, salt water, and more.

Following testing, the material that best met SNTech’s criteria was the optically clear Opti-tec 4210, a two-part, high hardness, room temperature curing polyurethane resin. Opti-tec 4210 has Shore D80 surface hardness, and boasts excellent long-term UV stability for outdoor use due to the incorporation of UV stabilisers and antioxidants. The resin has high mechanical strength, and its low viscosity makes it easy to mix and process. Based on both the commercial and technical conversations with Intertronics, the team at SNTech chose to incorporate both Opti-tec 4210 and IRS 3071, a black polyurethane potting compound, into its design.

Specifying an optical encapsulant or potting compound is a complex process, based on the environment, sector, and application your product will be supplied for. Considering your choice of optical encapsulant or potting compound early in the process, rather than later, can help increase the chances of the product passing the environmental testing and qualification phases. An experienced supplier can guide you through this process, helping you develop a reliable and repeatable process.