Posted to News on 16th Feb 2015, 12:39

Innovative inspection system for food and beverage industry

RNA Automation was recently approached with a request for a fully automated quality control and inspection system to handle and inspect plastic moulded components. The request related to a UK-based production requirement for a global leader in the food and beverage industry.

The system is required to handle, with minimum changeover, two components that are different sizes and shapes. A major consideration in this application was the complexity and fragility of the component parts. The system must not cause any damage to these parts, which have a detailed periphery.

Furthermore, the system must inspect from all three planes:

- Top for damage and OCR (optical character recognition);

- Bottom for diameter and damage;

- Side for damage, height and profile.

It is necessary for the system to detect and expel 100 per cent of rejected components but, critically, the components must not be damaged.

In addition, the customer required a complete system with the minimum requirements below:

- The system must be capable of operating at up to a rate of 1200 parts/minute

- It must be designed to meet food and GMP standards

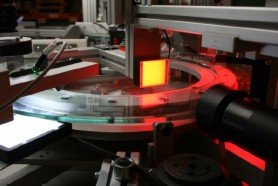

To enable the system to deliver 1200 parts per minute, the design utilised a twin-headed system with duplicate rotary feeders, conveyors, glass disc and reject segregation, with a common good part collection. This handling system involved the innovative idea of a 'rotating glass disc'.

The components are fed from a centrifugal feeder onto a conveyor system, then fed individually onto a rotating glass disc. Due to the design of the components, they have a tendency to 'castle' or 'double up', causing problems in the handling and inspection, resulting in false rejects. These problems are one of RNA strengths, and were solved with the expert use of gating and a non-contact accumulation system, while still ensuring that there was no damage caused to the components.

An encoder and trigger sensor are fitted on the rotating glass disc. Once a component part has passed through the trigger sensor an encoder count is stored. The PLC then tracks the components around the disc, triggering the appropriate cameras and ejecting reject components. Good components continue around the disc, being gently swept off down a chute into a collection box.

A PLC monitors a count of all good and reject components from both heads, which maintains correlation over continuous 24/7 production.

The cameras used in the inspection system utilise the latest technology high-resolution cameras with telecentric lens and lighting. This was required to achieve repeatability of measured values, with a one-micron resolution and 20-micron accuracy over 10,000 measured parts.

Key features and benefits

The system developed by RNA Automation:

- Provides a complete system with minimum changeover between components that are different in size and shape

- Offers minimum damage at maximum feed rates of up to and over 1200 parts per minute

- Offers cost-saving benefits such as labour cost savings and high production speeds

- Offers additional incremental benefits such as reduced downtime, improved quality control, raised standards of health and safety and better hygiene standard for food products

All of these benefits deliver a short payback period and impressive return on investment. To learn more about automated quality control and inspection systems from RNA Automation, go to www.rnaautomation.com.

Castle Bromwich Business Park

Tameside Drive

B35 7AG

UNITED KINGDOM

44 121 749 2566