Posted to News on 16th Mar 2011, 13:57

Industrial network gateways - the benefits for automation

Bjorn Franzen of HMS Industrial Networks explains how gateways can benefit industrial automation systems utilising serial, fieldbus and industrial Ethernet communications.

Networks in modern automation systems sometimes struggle to provide users with the ease of use and maintenance required. There are many reasons for this, such as the speed of development of new networks, the more complex demands put onto networks, and that networks are now being used to bridge not only between devices on the factory floor but now increasingly to connect onto business IT networks and services.

However, help is at hand in the form of industrial network gateways. These simple products are known by many names such as Babel boxes, Babel fish devices, X-gateways, black boxes, communicators, and their basic function is to simplify connection between two disparate devices or systems.

An industrial automation gateway is a device capable of linking two networks that use different base protocols. It is notable that there are over 150 open and proprietary networks available, so there are plenty of connection opportunities.

A network gateway can be implemented completely in software, completely in hardware, or as a combination of both, depending on the types of protocols they have to support. When talking about IT gateways, these at present are slightly different in their application than industrial network gateways; IT gateways tend to be used purely in Ethernet networks and normally include functionality such as acting as a firewall and/or as a router/switch, whereas an industrial network gateway should be seen as a translator between a machine and an industrial data network, and can be used to connect devices such as robots, control systems, motors and sensors to any industrial network, regardless of the communication protocol.

Gateway types

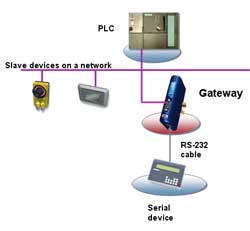

Industrial network gateways can be broken down into two basic functionality types. The first type acts as a link between two different networks, such as linking Profibus to Ethernet. The second type is used to connect simpler devices - such as sensors and weighing scales - using a simple connection, typically connecting a device's integral serial interface to a more complex network.

Bridging the gaps created in industrial data communication systems, modern industrial gateways for Ethernet-based connections now include support for web functions such as integrated web server with SSI, email client and FTP server. They also offer offering dual-port switching for Ethernet daisy-chaining, thereby saving the user additional network hardware costs.

The need for flexible and sustainable hardware platforms has led many gateway manufacturers to produce their own ASICs to help them meet the needs of the most modern Ethernet-based networks, while also allowing connection to legacy systems.

Applications for gateways

Gateways can be used in various industrial automation applications. Perhaps the most obvious is as a bridge between two PLC systems from different brands such as Siemens, Rockwell, Schneider, Mitsubishi, Beckhoff, ABB, etc. This can, of course, be achieved by using other methods, such as PLC rack-based communication cards, but this comes at the cost of a rack slot, and providing complicated PLC code that must be programmed, commissioned and maintained. Gateways, on the other hand, in most cases require no programming, need virtually no commissioning and offer the advantage of simple maintenance.

Another use of gateways is the segmentation of networks, where gateways are used to divide a network topology into logical segments. Gateways can allow clear divides to be created between different parts of the plant, both logically and electrically, where network performance optimisation and availability is needed.

Enterprise-level integration, where factory floor data must integrate with enterprise-level systems such as SCADA or SAP using OPC for dynamic data exchange, is another application for gateways, as is production line extension. Production line extension is where gateways are used to add segments of new machines with new network types into the manufacturing environment without major alterations and disruption to the existing production line.

Factory upgrades, where replacement of an old PLC system with up-to-date control equipment is needed, can, if gateways are used, allow the reuse of existing I/O modules and wiring infrastructure, thereby reducing upgrade costs considerably.

A major gateway application is providing PLC system extensions, where the gateway allows a simple, cost-effective way of connecting devices from several brands that use different network types. This enables the end user to select the best devices available for their application, rather than being reliant on what one manufacturer can provide.

The last scenario to mention here is the use of gateways to extend the life of products from a device manufacturer due to it extending its network options. Gateways can easily provide support for new network technologies, without the manufacturer having to redesign their products to meet the new networking needs.

When looking to extend, redesign or configure an industrial network, remember that gateways can help to optimise the network, both now and in the foreseeable future.

Follow the link for more information about the latest Anybus X-gateway and Anybus Communicator devices from HMS Industrial Networks.

The Venture Centre, Sir William Lyons Road

Warwick University Science Park

CV4 7EZ

UNITED KINGDOM

+44 (0)1926 405599