Posted to News on 22nd Nov 2012, 10:56

Industrial gear unit range now covers 25 kNm to 242 kNm

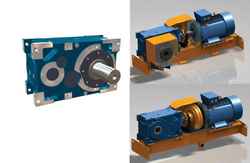

Nord Drivesytems is expanding its NORDBLOC SK Industrial Gear Unit range with four new smaller models with a choice of helical or bevel-helical gear stages. The new gear units, in sizes 7, 8, 9 and 10, are available for output torque from 25kNm to 50kNm in the same characteristic UNICASE monobloc design as the present SK range that extends to 242kNm in sizes 11, 12, 13 and 15.

The durable and robust NORDBLOC SK range is aimed at heavy engineering applications throughout all industries. Units are supplied as a pre-assembled modular sub-assembly mounted on a choice of base frames, complete with gearbox, motor and coupling, along with a comprehensive and flexible range of options and accessories. ATEX, food and beverage, and other sensitive-environment versions are fully available.

These scalable products are application-matched from a comprehensive checklist of gear unit selection criteria to ensure that the units provide optimal performance and a long service life. This extends from installation environment and operational duty frequency, to a full analysis of thermal, load-bearing, torque, speed and other critical dynamic factors. By specifying a complete sub-assembly, customers are able to reduce their own project management burden and reduce timescales and costs by using the Nord design service to manage all aspects of the application. This approach also ensures that project planning, purchasing and system commissioning are more straightforward.

The modular system takes care of gearbox and motor orientation with options of elastic or fluid couplings and a choice of fixed or swing base frames. Further options include output shaft types and positions, motor-gearbox coupling, drum or disc brakes, lubrication management, radial or axial cooling fans, auxiliary drives, torque support, surface protection and more.

Wide choice of ratios

As with the existing larger units, both two- and three-stage gear units are available with a wide choice of ratios extending through the range. The symmetrical UNICASE gearbox design permits mirror-image installation for dual-drive applications. Nord's own wide range of IEC frame energy-saving three-phase motors are used throughout, and NORD SK 500E frequency inverters are available to offer complete gear unit and drives with high-performance motor control, and connection to all current factory networking communications systems.

The UNICASE gear unit housing system employed in the NORDBLOC SK series industrial gear units draws on the proven benefits from the concept Nord originally developed more than 30 years ago. The one-piece design, produced on specialised CNC machines, yields high levels of precision, rigidity and strength. As all bearings are mounted directly into the cast iron UNICASE housing and, with no dividing seams between the drive and gear unit, the design allows shaft axes to be staggered in a more compact, space-saving arrangement that permits the use of larger roller bearings. The result is a much longer operational life with quieter running and reduced maintenance burden when compared with split housing designs.

The new size 7,8,9 and 10 Industrial Gear Units are comprehensively covered in the G1051 catalogue that is supplementary to the full G1050 catalogue for the larger units - which includes a complete resource for project planning. Both catalogues are available for download from www.nord.com or in hard copy on request. Alternatively, follow the link for more information about NORDBLOC SK Industrial Gear Units.