Posted to News on 23rd Jan 2017, 00:00

Drum motors versus gear motors in food conveyors

The Department of Food Science at the University of Parma in Italy has carried out a comprehensive system comparison between two distinct drive technologies in the food processing industry.

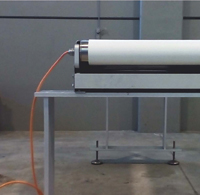

Conveyor belt systems in the food processing and packaging industries have traditionally been using external gear motors as belt drive mechanisms. Drum motors have become increasingly popular as alternative belt drive technology due to their clear advantages in terms of space for installation, operators’ accessibility to the belt and suitability for washdown areas.

A neutral and objective comparison is needed to support the food industry in choosing the optimum belt drive for various applications and factory areas. Under a research contract between the Inter-departmental Centre SITEIA at the University of Parma and Interroll, Professor Davide Barbanti, associate professor at the University of Parma and scientific chair of SITEIA.PARMA, and his research team conducted a far-reaching comparison along six evaluation criteria:

- Hygiene

- Installation and maintenance

- Energy efficiency

- Noise

- Working temperature

- Space requirements

Belt conveyors are widely used in the food industry, too. They can be used to transport raw foods, food ingredients, final products, by-products, food waste, various containers, packed food products, and more. The possible influence of the conveyor system on the safety and quality of the food can dramatically vary, depending on:

- The material handled by the conveyor

- The area of the food factory where the conveyor is installed

- Any zoning and segregation adopted in the food factory

In any case, the design and installation of the belt conveyor plays an important role and it musts at least comply with all regulations for equipment intended to be used in the food industry. In comparing gear motors with drum motors for the specific application of belt conveyors in the food industry, three different use cases were considered:

- A belt conveyor used in a non-food area of a food factory

- A belt conveyor used in a food area of a food factory and intended to be dry cleaned or manually cleaned

- A belt conveyor used in a food area of a food factory and intended to be washed

“For this study, which included scientific measurements and experimental trials, our aim was to carry out a comparison between state-of-the-art components,” says Professor Barbanti. “We designed three distinct use cases to simulate the different areas of a food processing plant, from a washdown application to a packaging line. A total of 36 different experiments were run over a nine-month period and yielded interesting results, showing the drum motor as a particularly attractive technology for conveyor belts in the food industry.”

The benefits of drum motors

The study concluded that the drum motor offers interesting benefits from the hygienic point of view, which in the case of the food processing industry is the most relevant among the six criteria. Thanks to its compact design, it is generally evaluated more positively against almost all evaluation sub-criteria than the selected gear motors. The risks of soil accumulation and cross-contamination are significantly lower for drum motors than for the most commonly used gear motors.

Furthermore, in case of washdown areas, the drum motor offers significant advantages in terms of cleanability in-place as all components are embedded inside the roller and no protective enclosure is needed. This will result in considerable time and cost savings for operators with regards to their cleaning routine. The only weakness of drum motors from the hygienic point of view is the potential risk of contamination by lubricant. Even though synthetic food-grade oil is used, this can be a critical point and further effort in validation should be done to ensure adequate reliability of the dynamic radial shaft seals.

While the study sought to use equipment reasonably suitable for the various applications considered, it noted that unfortunately gear motors with similar specifications to the one selected for the non-food use-case of this study, often are used also in food areas and even washdown food areas. It is to be supposed that such choices are motivated purely by economic reasons, but obviously this bad practice can lead to hygienic problems. Moreover, drum motors offer big advantages in term of space for installation, making them the only possible choice in some special applications or layouts. Having fewer single components than gear motors, the installation of drum motors is generally simpler and faster. The lower weight, as observed in food and washdown use cases, brings additional advantages for operators in terms of ergonomics and reduces the risk of injuries.

With regard to maintenance, the study concluded that onsite maintenance operations become more impractical as the piece of equipment becomes more specialised. Food areas and washdown areas generally need very specialised pieces of equipment so, in these use cases, there are no significant differences between the gear motors and the drum motors.

With regard to the other evaluating criteria (energy consumption, noise and overheating), the evaluation was carried out using experimental trials on specific commercial drum motors and gear motors. The results are strongly influenced by the choice of the pieces of equipment. Generally, slight or insignificant differences are found for state-of-the-art pieces of equipment (food and washdown use cases), depending on the specific design and construction of the selected components.

“Food safety is a critical matter for all players in the food processing industry but too often we still find gear motors that don’t satisfy the key principles of hygienic design in areas where food is processed,” says Professor Barbanti. “Supposedly such choices are dictated by economic reasons. We hope that the research, which we were able to conduct with the support of Interroll, and the resulting study will be considered by decision-makers in the food industry as practical recommendation for their equipment choices regarding their processing and packaging lines.”

The results of the study have been published in the whitepaper “Comparative evaluation between gear motors and drum motors in the food industry,“ and can be downloaded at www.interroll.com/downloads.